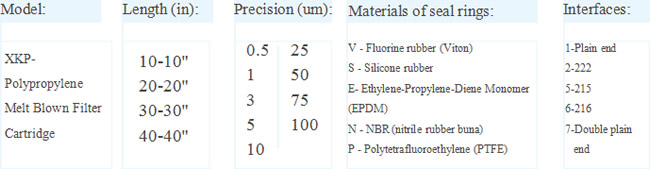

GrooveMeltBlownFilterCartridgeismadeof100%purepolypropylenemicrofibermaterials.Polypropyleneslicesaremelted,blown,hauled,andmoldedathightemperatures.Thedouble-l……

Groove Melt Blown Filter Cartridge is made of 100% pure polypropylene microfiber materials. Polypropylene slices are melted, blown, hauled, and molded at high temperatures. The double-layer fiber structure of the filter cartridge composing inside fine fiber and outer coarse and loose fiber layers can effectively reduce the loss of pressure and maintains a stable filtration efficiency. Rely on their own adhesion and entanglement, microfiber materials form a three-dimensional microporous structure randomly in space, in which the inter-fiber connection does not require any adhesive. Particularly it has a gradient change of radial fibers, and is a synthesis of porous and fabric filtering medium.

Polypropylene melt blown filter cartridge has characteristics of high intensity, chemical resistance, high capacity of impurity capturing, high filtration accuracy, etc. It is applicable to a variety of water treatment and fluid filtration.

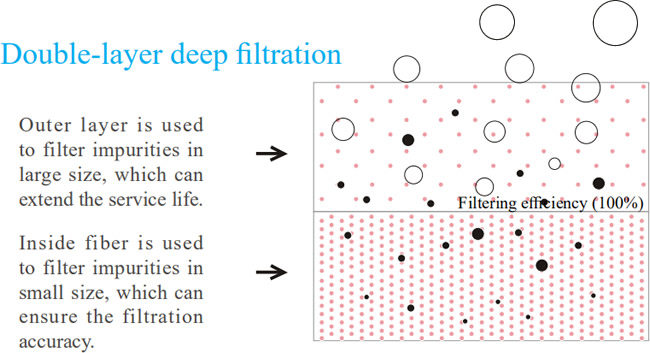

1、Double-layer filtration, outer layer is used to filter large impurities and to extend the service life, inside fiber is used to filter small impurities and ensure the filtration accuracy.

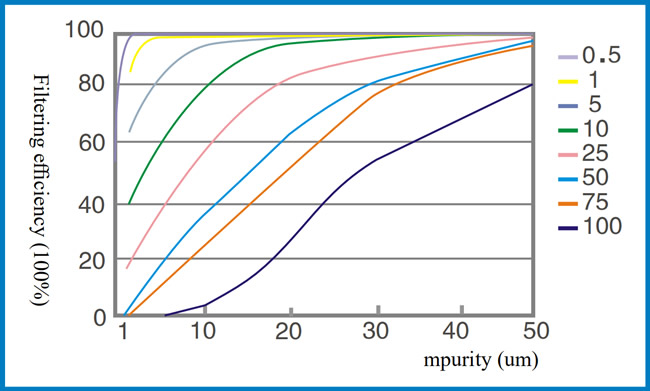

2、Filter cartridge pore diameters are uniform in density, and filtration efficiency can be up to more than 99%.

3、Filter cartridge is not easy to be blocked, and it has small filtration resistance and large flow rate.

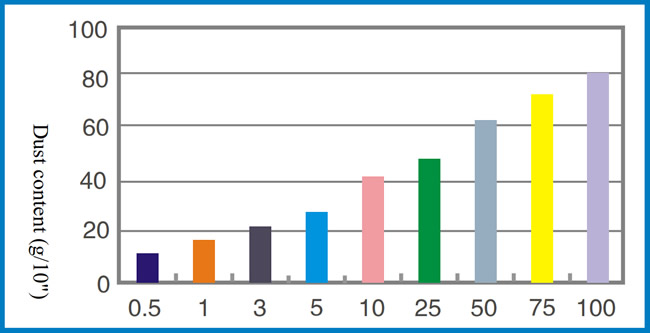

4、High impurity capacity, and long service life.

5、Made of 100% ultrafine pure PP fiber and has a high filtration accuracy and chemical resistance.

Maximum Operation differential pressure: When it is 80℃ , 1.2kg/cm2

When it is 60℃ , 2.1kg/cm2

When it is 20℃ , 4.2kg/cm2

Recommended replacing differential pressure: 2.1 kg/ cm2

Maximum operating temperature: 80℃

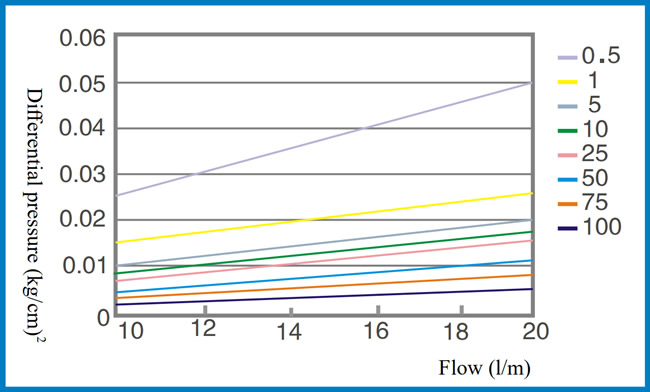

Flow pdifferential ressure table

Filtration efficiency table

Dust content table (g/10)

1、Pure water pre-filtration

2、Electro-coating filtration

3、Developing solution filtration

4、Medium/Low-viscosity pharmaceutical liquid filtration

5、Edible oil filtration

6、Plating solution filtration

7、Circulating water filtration