ThematerialmanufactureofPTFEfoldablefiltercartridgeadoptstheadvancedbiaxialextensiontechnologyandhasaporosityof85%-90%.Theporesizedistributionisuniformandithast……

The material manufacture of PTFE foldable filter cartridge adopts the advanced biaxial extension technology and has a porosity of 85%-90%. The pore size distribution is uniform and it has the characteristic of high flow rate, low differential pressure and long service life.

The unique tetrafluoro structure of PTFE give it an excellent characteristic of resisting to strong acid and alkali solution. Especially, it is suitable to filter the strong acid and alkali solution in electronic production processes.

1、PTFE has an excellent chemical resistance.

2、Filtering area is over 0.9m2, low differential pressure, and large volume. The ratio of filter hole is as high as 85%-95%.

3、Manufactured in a dust-free environment, and filter cartridge is of high-level cleanliness.

4、Filter cartridge integrity testing

5、Connector size and the ring material fully comply with the international standards.

6、Absolute precision of 0.01 μm for air filtration to filter out bacteria, virus and microorganism in the air.

PTFE strong acid weak acid weak base strong base solvent

When applied to liquid

Maximum Operation differential pressure: When it is 95 ℃ : 1.4 kg/cm2

When it is 20 ℃ , 5.6 kg/cm2

Maximum operating temperature: 90 ℃

External diameter 63mm/ Inner diameter 28mm

When applied to liquid

Maximum Operation differential pressure: 7 kg/cm2

Maximumoperating temperature: 90 ℃

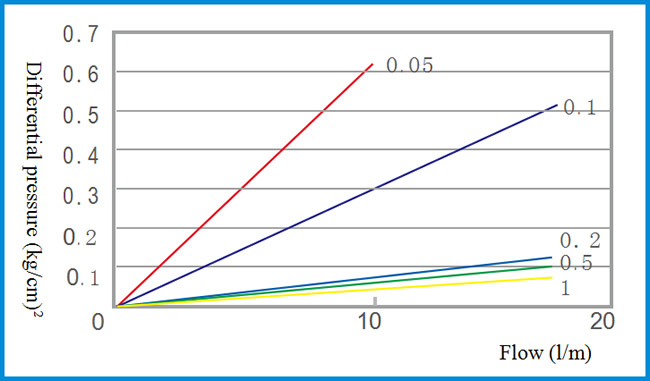

Flow pdifferential ressure table

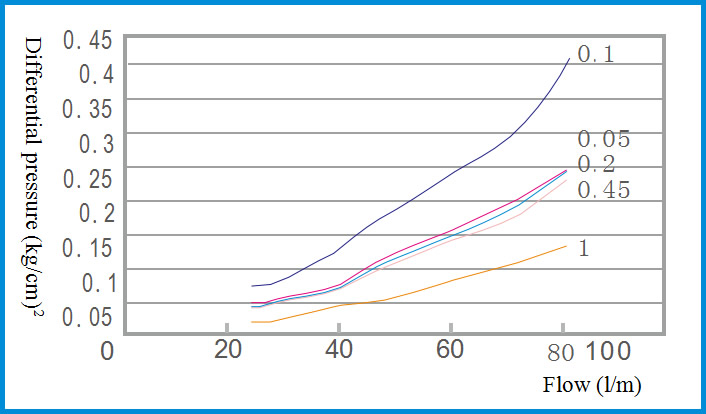

Flow pdifferential ressure table

1、Pure water pre-filtration

2、Precision filtration by solvent

3、Precision filtration by photoresist

4、80 ℃ filtration

5、Aseptic filtration

6、Solvent stripping