The integrity test should be conducted after the filter is used. The integrity test methods specified by GMP include bubble point, diffusion flow or water immersion. The wetting solution can be either a standard reagent (water, alcohol, etc.) or a process fluid can be used.

1. Principle: according to the difference of surface tension or other physical parameters between different fluids, the wettability integrity test value of products can be obtained by statistical method.

2. Type of filter element:

Membrane filter with precision less than 1 um:

Membrane final filter

Sterilizing membrane filter

Virus removal membrane filter

Hydrophobic gas filter

3. Test items: bubble point, diffusion flow, pressure holding or water immersion;

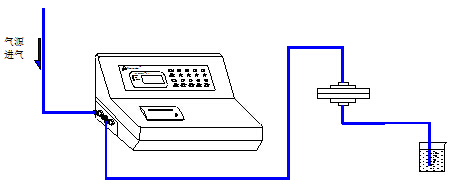

4. Connection method:

Test connection diagram of cartridge filter:

Connection diagram of flat filter test:

5. Integrity testing steps

a. Wet the filter element or diaphragm with wetting solution;

b. Connect the air source and power supply with the integrity detector, and then connect with the filter shell or holder that can be used for integrity detection;

c. Start the integrity detector and input the test program and data;

d. Put the wetted filter element or membrane into the filter shell and holder, and the integrity detector will automatically detect and judge the results.

6. Notes for integrity tester

1) Service conditions:

a. Power supply: 100 ~ 240 VAC, 50 / 60Hz, 1.6A;

b. Gas source requirements: clean, normal temperature, dry, oil-free compressed air or nitrogen;

c. Air source pressure: < 7000mbar, common gas source pressure: 6000mbar;

d. Working temperature: 5 ~ 40 ℃;

e. Relative humidity: 20 ~ 80%.

2) Maintenance

a. Handle with care;

b. Ensure the stability of power supply voltage;

c. Ensure gas quality and pressure stability;

d. Keep the instrument clean;

e. Avoid liquid entering into the internal pipeline of the instrument;

f. Please consult the instrument supplier for regular calibration of pressure sensor

g. When it is not used for a long time, the filter integrity detector shall be placed in the packing box and stored in a dry place